Nitrogen oxides (NOx) in diesel engine exhaust are extremely harmful to people’s living environment, as a result, countries and regions around the globe have issued relevant regulations to significantly control and reduce NOx emissions from motor vehicles. With increasingly stringent emission regulations established by more and more countries, it is hard to satisfy the requirements of NOx emissions only by combustion optimization and other in-machine control measures. Selective catalytic reduction (SCR) technology is the mainstream control method at present. The working principle of SCR system is to inject a liquid-reductant agent into the exhaust stream of a diesel engine and reduce NOx to ammonia and water with the help of catalysis. In SCR system, reductant source is usually urea solution which is consumable and impossible to reuse. Therefore, the liquid level of urea solution needs to be monitored by the system in real time so as to replenish the urea solution regularly.

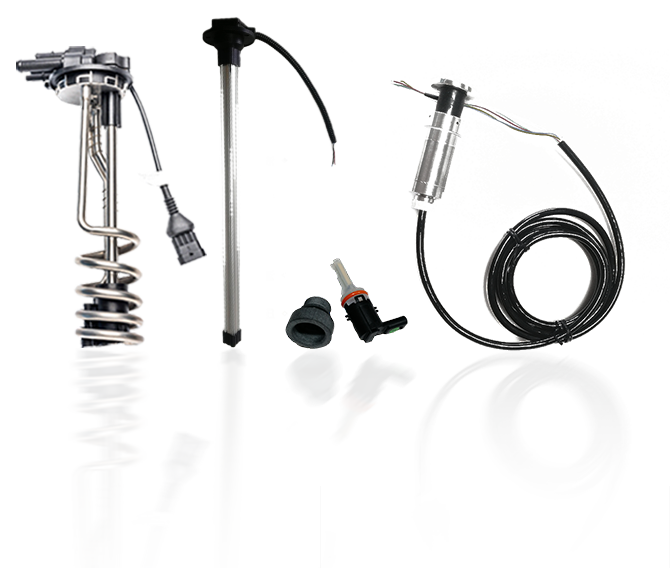

Misensor provides urea level sensors that can measure the urea level stably and reliably for our client in Italy. The client is a leader in the aspects of thermoplastic pipes, injection-molded plastic and rubber components in industrial and automotive fields. Since 1981, the company has established four factories in Italy, one factory in Romania, one branch and a warehouse in Detroit and its products have been exported to the whole world.

Our product is not only compact in design, simple in structure and cost-effective in use, but also can meet the needs of durability and assembly in different applications. The client integrates the urea level sensor with quality sensor and temperature sensor so as to monitor the level, quality and temperature of urea in tank in real time. The float of the liquid level sensor bobs up and down following the liquid level of urea so that the driver can read the remaining amount of urea in tank on the instrument panel and replenish urea solution in time. The integrated sensor can also monitor the concentration of urea solution and offer relevant signals to the system. Overfilling or wrong mixed liquid can be monitored immediately by the system, which ensures the quality of urea in tank and the regular functions of SCR system all the time.

The product can satisfy the requirements of emission systems in heavy trucks, cargo trucks, engineering machinery, agricultural machinery, etc. It has been widely used and recognized by many OEM manufacturers.